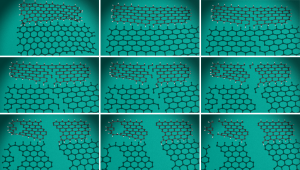

Organic molecules, such as polymers or biopolymers can partly cover enormous tensile strengths. In the shown example of a graphene nanoflake, which has been tested on tensile strength, it has been more than 250 times bigger than for steel!

This strong property shall be used in a composit material, to substantially change its properties compared to the pure material.

The strength of the molecule has its origin in the chemical bond. Material cracks do not open normally within molecules, but between molecules. Therefore the intermolecular forces are an important part of the models. It is possible, to check virtually polymers or its composits on the tensile strength without knowing the macroscopic material properties in advance.